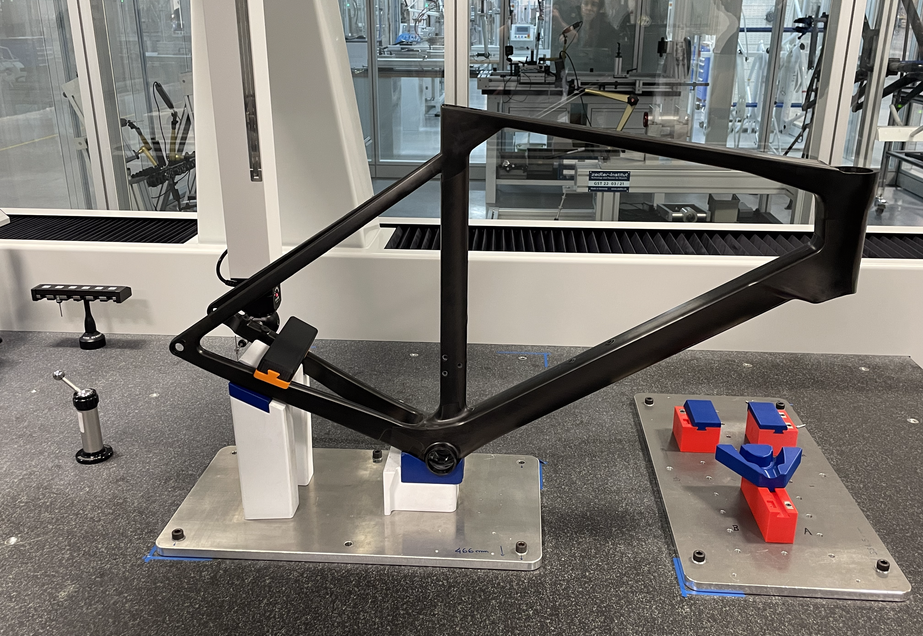

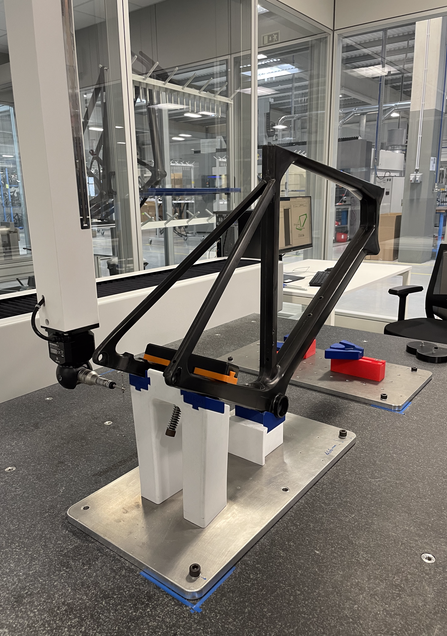

High-tech made in Europe - the PAVO IV carbon frame

|Insights

High-quality carbon fibres, full-monocoque construction and autoclave production in Europe: the PAVO IV defines highest standards in carbon frame manufacturing.